Polyethylene Terephthalate Glycol, widely known as PETG, has become one of the most versatile and trusted thermoplastics in modern manufacturing. Positioned between PET and polycarbonate in terms of performance, PETG offers a rare balance of strength, clarity, chemical resistance, and ease of processing. This unique combination has made it a preferred material across industries ranging from packaging and medical devices to 3D printing and consumer products.

As demand grows for materials that are durable, cost-effective, and environmentally responsible, PETG continues to stand out. Engineers, designers, and manufacturers value its reliability under stress, while end users appreciate its transparency and safety. This article provides a comprehensive, expert-level overview of PETG, exploring its composition, defining properties, real-world applications, and the benefits that make it an increasingly popular material choice.

What Is PETG and How It Is Made

PETG is a modified version of PET, created by adding glycol during polymerization to reduce crystallinity and improve performance characteristics. This chemical adjustment prevents brittleness and enhances flexibility, resulting in a tougher, clearer plastic that is easier to thermoform and process. Unlike standard PET, PETG does not become hazy when heated, making it ideal for applications requiring optical clarity and consistent surface quality. Its amorphous structure allows for uniform forming without stress cracking, which is a critical advantage in precision manufacturing environments.

From a production standpoint, PETG is typically manufactured through extrusion or injection molding processes, depending on its intended use. Sheets, filaments, and molded parts can all be produced with minimal material waste. Because PETG melts at a lower temperature than many engineering plastics, it requires less energy to process, improving efficiency and reducing costs. This manufacturing flexibility contributes significantly to PETG’s widespread adoption across multiple industries.

Key Properties That Define PETG Performance

One of the most notable properties of PETG is its exceptional impact resistance. It can withstand repeated stress and sudden force without cracking, making it far more durable than acrylic and standard PET. At the same time, PETG maintains excellent transparency, often rivaling glass in visual clarity. This combination of strength and aesthetics makes it particularly valuable in protective coverings, display products, and packaging where both appearance and durability matter.

PETG also offers strong chemical resistance, especially against acids, alkalis, and cleaning agents commonly used in industrial and medical settings. It performs reliably across a wide temperature range and retains its mechanical integrity under prolonged use. Additionally, PETG is inherently food-safe and compliant with many regulatory standards, further expanding its usability. These balanced material properties position PETG as a practical solution for applications that demand reliability without excessive cost or complexity.

Common Applications Across Industries

The versatility of PETG has led to its adoption in a broad spectrum of industries. In packaging, it is widely used for food containers, beverage bottles, and blister packs due to its clarity, strength, and safety profile. Retail and commercial sectors frequently rely on PETG for signage, point-of-sale displays, and protective barriers, where visual appeal and impact resistance are essential. Its ability to be easily thermoformed allows manufacturers to create complex shapes with consistent quality.

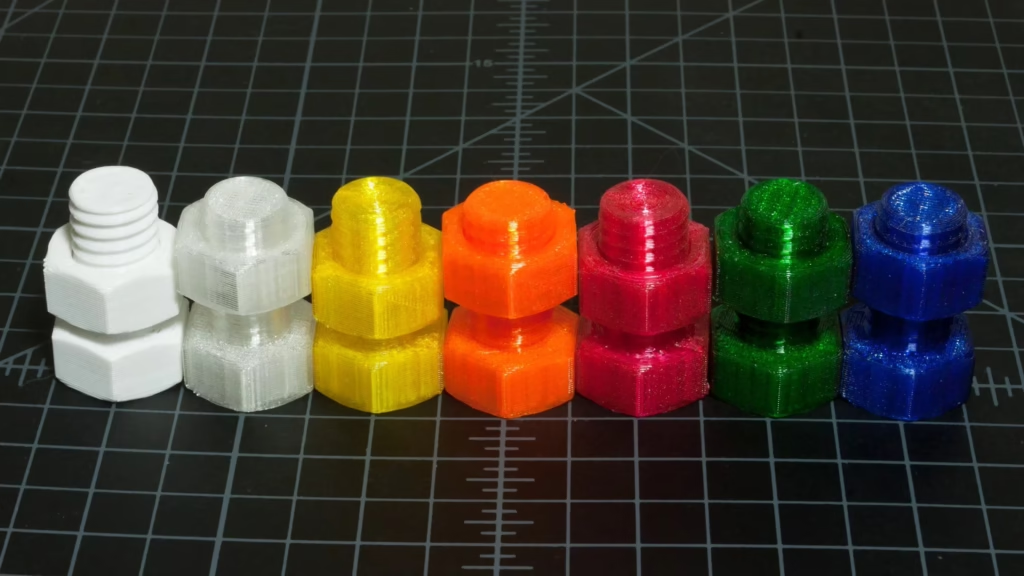

In the medical and healthcare fields, PETG is valued for its chemical resistance and ease of sterilization. It is commonly found in medical trays, device housings, and protective equipment. The rise of additive manufacturing has further expanded PETG’s role, particularly in 3D printing. PETG filament offers improved toughness and flexibility compared to PLA, making it suitable for functional prototypes, mechanical parts, and end-use components.

Benefits of Using PETG Compared to Other Plastics

When compared to alternative materials such as acrylic, polycarbonate, or PVC, PETG offers a compelling set of advantages. It is significantly more impact-resistant than acrylic while being easier and safer to process than polycarbonate. Unlike PVC, PETG does not release harmful chlorine-based compounds during manufacturing or disposal, making it a cleaner and more sustainable option. These benefits reduce production risks while maintaining high-performance standards.

Cost efficiency is another major benefit of PETG. Its lower processing temperature reduces energy consumption, and its durability minimizes material replacement over time. PETG also bonds and machines easily, allowing manufacturers to streamline fabrication without specialized equipment. For designers and engineers seeking a material that balances performance, safety, and affordability, PETG consistently proves to be a smart and adaptable choice across a wide range of applications.

Conclusion: Why PETG Continues to Gain Momentum

PETG has earned its reputation as a high-performance plastic by delivering consistent results across demanding applications. Its unique blend of strength, clarity, chemical resistance, and processing ease sets it apart from many conventional thermoplastics. Whether used in packaging, medical devices, industrial components, or 3D printing, PETG adapts well to modern manufacturing requirements without compromising quality or safety.